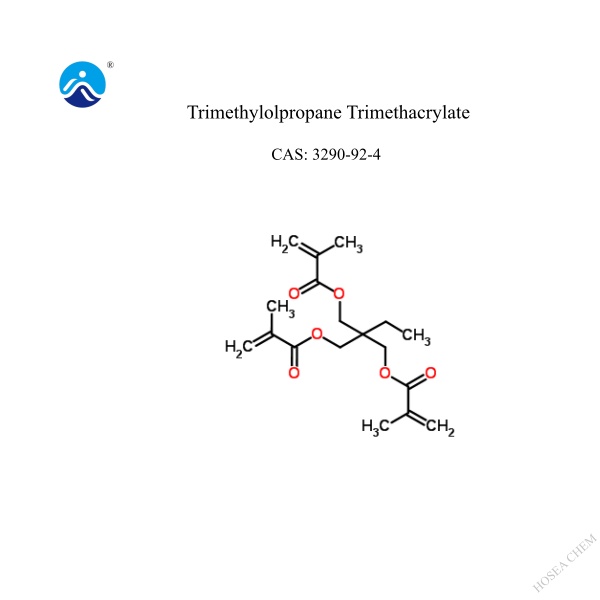

Trimethylolpropane Trimethacrylate

Hosea Chem® has been supplying Trimethylolpropane Trimethacrylate (CAS 3290-92-4) (Rubber Crosslinking Agent TMPTMA) with high quality and competitive price for many years, covering most of the European, American, etc. Send Inquiry

Product Description

Trimethylolpropane Trimethacrylate

Rubber Crosslinking Agent TMPTMA

Specification of Product

Product Name : Trimethylolpropane Trimethacrylate; TMPTMA; 2,2-Bis(methacryloyloxymethyl)butyl methacrylate

Grade: Ⅰ Grade

Molecular Formula: C18H26O6

Cas No.: 3290-92-4

Trimethylolpropane Trimethacrylate Quality Standard

Appearance: Light yellow liquid

Acid grade (mgKOH/g): ≤ 0.35

Density (25℃, g/cm3): 1.060

Index of refraction, no05: 1.4700

Moisture: ≤ 0.20

Packaging, transportation, and storage

Package:200, 25kg/ bag.

Stored in a cool, ventilated and dry place, fire-proof, moisture-proof and sun-proof.

Trimethylolpropane Trimethacrylate Applications

1. Co-vulcanizing Agent

TMPTMA is used in synthetic rubber to improve its corrosion resistance and aging resistance, increase its hardness and heat resistance, and absorb the odor of peroxidation products (such as DCP) produced during the vulcanization process.

Trimethylolpropane Trimethacrylate helps the rubber become more malleable during the mixing process, making the vulcanized rubber harder.

Trimethylolpropane Trimethacrylate is suitable for MBR, EPDM, ACM, CR, etc.

2. Cross-linking Agent

TMPTMA can reduce radiation dose and time, increase cross-link density, and offer low viscosity, high cross-linking properties, low vapor pressure, and high curing speed.