Sodium Carboxymethyl Cellulose

Hosea Chem®, as a supplier and manufacturer of sodium carboxymethyl cellulose (CMC), has engaged in production, development, and marketing of Sodium Carboxymethyl Cellulose (CMC)for over 30 years.

【 E-mail: sales@hoseachem.com 】 Send Inquiry

Product Description

1.Product introduction of Sodium Carboxymethyl Cellulose

CAS: 9004-32-4

H.S: 39123100

EINECS: 900-432-4

Chemical Formula: [C6H7O2(OH)2OCH2COONa]n

Another name: Carboxymethylcellulose , CMC , CMC Na , Sodium Carboxymethylcellulose , E466 , Cellulose Gum.

CMC is anionic cellulose ether with macromolecular structure. It is odourless, tasteless, and non-toxic with white or faint yellow powder or particles. It can easily dissolve in water, and transfer into the colloidal solution; and it cannot dissolve in ethanol, ether, acetone, and other organic solvent.

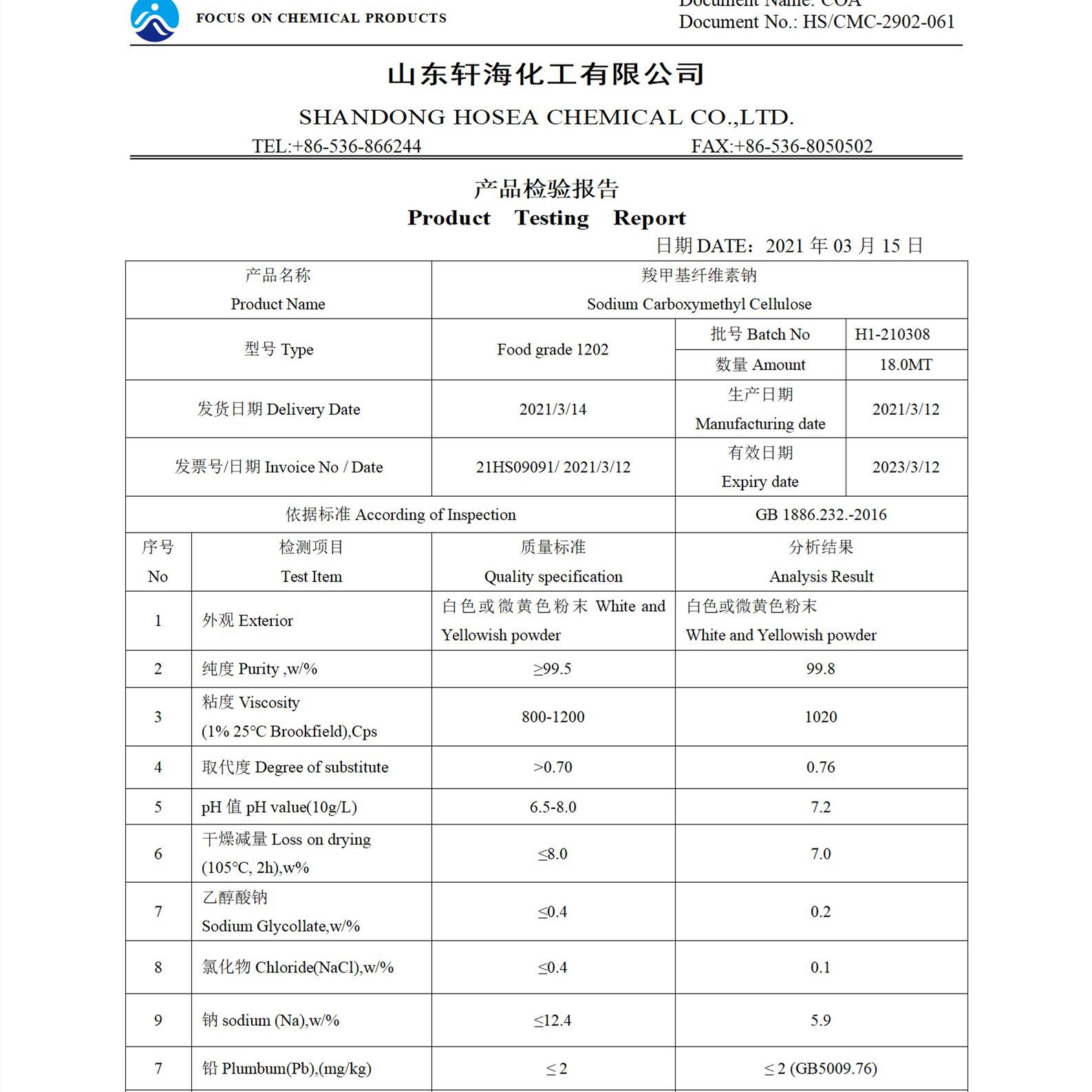

2.Product Parameter(Specification) of Sodium Carboxymethyl Cellulose

The main indicators for measuring the quality of sodium carboxymethyl cellulose are the viscosity, degree of substitution (D.S) and purity.

According of Inspection (food grade CMC): GB1886.232-2016, E 466 and FCC IV standard.

According of Inspection (Oil Drilling grade CMC): API 13A, GB/T 5005, OCMA standards.

For details of product parameters, please contact us.

3.Product Feature And Application of Sodium Carboxymethyl cellulose

1) Food Grade Sodium Carboxymethyl cellulose (CMC, FH9 , FVH9, FVH6, FH6)

Sodium Carboxymethyl cellulose (CMC) is widely used in food production such as liquid beverages, acidic milk drinks, fruit juice, solid instant drinks, roasting, ice cream, instant noodles, condiments and other foods. It has good thickening, stabilization, emulsification, suspension, dispersing and improving taste. Generally, the recommended dosage is 0.3-1.0%.

LD-F-601 | LD-F-602 | LD-F-603 | LD-F-604 | LD-F-605 | LD-F-606 | LD-F-607 | LD-F-608 | |

Viscosity 1% , 25℃, mPa.s | 100-500 | 500-1000 | 1000-2000 | 2000-3000 | 3000-4000 | 4000-5000 | 5000-6000 | >6000 |

Appearance | White to white cream powder | |||||||

Degree ofSubstitution(D.S) | 0.7-0.9 | |||||||

Purity % | ≥99.5 | |||||||

pH (25℃, 1% solution) | 6.0-8.5 | |||||||

Loss ondrying(H2O),% | ≤8.0 | |||||||

Heavy Metal(Pb) % | ≤0.0015 | |||||||

Fe, % | ≤0.02 | |||||||

As, % | ≤0.0005 | |||||||

Pb, % | ≤0.0015 | |||||||

Remark: | we can produce according to your requirement. | |||||||

LD-F-H301 | LD-F-H302 | LD-F-H303 | LD-F-H304 | LD-F-H305 | LD-F-H306 | |

Viscosity 1% , 25℃, mPa.s | 20-100 | 100-500 | 500-1000 | 1000-2000 | 2000-3000 | >3000 |

Appearance | White to white cream powder | |||||

Degree ofSubstitution(D.S) | >0.9 | |||||

Purity % | ≥99.5 | |||||

pH (25℃, 1% solution) | 6.0-8.5 | |||||

Loss ondrying(H2O),% | ≤8.0 | |||||

Heavy Metal(Pb) % | ≤0.0015 | |||||

Fe, % | ≤0.02 | |||||

As, % | ≤0.0005 | |||||

Pb, % | ≤0.0015 | |||||

Remark: | we can produce according to your requirement. | |||||

2) Mining Grade Carboxymethyl Cellulose (CMC, CMC-Na, Cellulose Gum)

Carboxymethylcellulose is used in mining industry as pellet binder and floating selection inhibitor.

CMC is a component of the binder for mineral dust shaping, and the binder is an indispensable ingredient in pellet forming. It can improve the character of wet pellet, dry pellet and calcinated pellet. Due to its good binding property and pellet forming property, the green pellet with CMC has excellent antiknock performance, high compressive strength and dropping resistance. It can also increase the grade of pellet. CMC is adjusting agent in floating selection process, it is used as silicate gangue inhibitor, controlling the lead in copper and lead separating, sometimes it is used as dispersant for mineral mud.

MI-A | MI-B | MI-C | MI-D | MI-E | |

Appearance | White to white cream powder | ||||

Viscosity 1% , 25℃, mPa.s | 100-200 | 200-500 | 500-1000 | 1000-2000 | >2000 |

Purity, % | ≥80 | ≥90 | ≥95 | ≥98 | ≥99 |

Degree ofSubstitution (D.S) | 0.70-0.90 | >0.9 | |||

pH (25℃, 1% solution) | 6.0-8.5 | ||||

Loss ondrying(H2O),% | ≤10.0 | ||||

Remark: | we can produce according to your requirement. | ||||

3) Battery slurry Grade CMC (carboxymethyl cellulose , CMC Na,Sodium Carboxymethyl cellulose)

Sodium carboxymethyl cellulose acts as a binder, dispersant, and thickener in the battery industry. Sodium carboxymethyl cellulose can stabilize the structure of the pole piece. Prevent sediment of active substances and improve performances of charging and discharging.

4) Painting Grade Sodium Carboxymethyl Cellulose

CMC, as one kind of protective colloid, will enhance stability of emulsion polymerization system to evenly scatter the additive of pigment and filler etc. Into painting so as to impart it will good pigment adhesion effect. Sodium CMC can evidently improve the viscosity of painting latex, anti-splash and sag resistance of painting in order to improve the workability of painting.

PG-7201 | PG-7202 | PG-7203 | PG-7204 | PG-7205 | |

Appearance | White to white cream powder | ||||

Viscosity 1% , 25℃, mPa.s | 2000-3000 | 3000-4000 | 4000-5000 | 5000-6000 | 6000-7000 |

Purity, % | ≥98 | ||||

Degree ofSubstitution(D.S) | 0.80-0.90 | 0.70-0.90 | 0.70-0.80 | ||

pH (25℃, 1% solution) | 6.0-8.5 | ||||

Loss ondrying(H2O),% | ≤10.0 | ||||

Remark: | we can produce according to your requirement. | ||||

5) Ceramic Grade CMC Na

When used in binder, Carboxymethylcellulose can improve its viscosity, make it easier to shape up, increase 2-3 times of its fracture resistance, and improve its stability. Also, the usage of CMC in machining operation ceramics can reduce the processing cost. What’s more, the addition of the “modified CMC” can make the water in the binder evaporate evenly, prevent the binder from dry and crazing, which in turn can increase the rates of the superior products.

In the production of ceramics, CMC is used in the idiosome of the ceramics, the glaze slip and fancy glaze. The recommended dosage of CMC in the idiosome of the ceramics, the glaze slip and fancy glaze is 0.03-0.2%, 0.05-0.2%, and 1.4-4.0% separately.

C-8 | C-9 | C-10 | C-11 | C-12 | |

Appearance | White to white cream powder | ||||

Viscosity 1% , 25℃, mPa.s | 300-500 | 500-1000 | 1000-2000 | 2000-3000 | >3000 |

Purity, % | ≥70 | ≥90 | ≥98 | ≥98 | ≥98 |

Degree ofSubstitution(D.S) | 0.70-0.80 | 0.80-0.90 | ≥0.9 | ≥0.9 | 0.80-0.90 |

pH (25℃, 1% solution) | 8.0-11.0 | 6.0-8.5 | |||

Loss ondrying(H2O),% | ≤10.0 | ||||

Remark: | we can produce according to your requirement. | ||||

6) Detergent Grade CMC

Sodium Carboxymethyl Cellulose can be used as fouling resistance and depositional agent, which can prevent the fouling from adhering to the textile when it is washed with the synthetic detergent. You can get the perfect result by adding 0.5-2.0% CMC to the synthetic detergent. When it is used in liquid or pasty detergent, it can improve the stability and thickening the detergent. CMC also increase the thickness of washing liquid and make it stable.

LD-YT-1 | LD-YT-2 | LD-YT-3 | LD-YT-4 | LD-SO-1 | |

Appearance | White to white cream powder | ||||

Viscosity 1% , 25℃, mPa.s | ≥5000 | ≥3000 | ≥1500 | ≥2100 | 800-1200 |

Purity, % | ≥99.5 | ≥90 | ≥99.5 | ≥99.5 | ≥99.5 |

Degree ofSubstitution(D.S) | ≥0.7 | ≥0.7 | ≥0.9 | ≥0.7 | ≥0.7 |

pH (25℃, 1% solution) | 6.5-8.5 | ||||

Loss ondrying(H2O),% | ≤10.0 | ||||

7) Toothpaste Grade CMC (Sodium Carboxymethyl Cellulose)

Toothpaste is a dispersed system composed of abrasives, moisturizers, former, essence and water etc. CMC is one of the most important raw materials in toothpaste and plays the role of mixing evenly the fluid and solid material, making the toothpaste molding, flowing, moderate thickness, brightness and smoothness. Furthermore, it helps the powders and liquids emulsify evenly to become the stable soliquoid, and plays the extremely important role in stability and diffusivity.

LD-TP-701 | LD-TP-702 | LD-TP-703 | LD-TP-704 | LD-TP-705 | LD-TP-706 | |

Viscosity 2% , 25℃, mPa.s | 400-1000 | 1000-1500 | 1500-3000 | 300-500 | 500-1000 | >1000 |

Degree ofSubstitution(D.S) | ≥0.9 | ≥1.0 | ||||

Appearance | White to white cream powder | |||||

Purity % | ≥99.5 | |||||

pH (25℃, 1% solution) | 6.0-8.5 | |||||

Loss ondrying(H2O),% | ≤8.0 | |||||

Heavy Metal(Pb) % | ≤0.0015 | |||||

Fe, % | ≤0.02 | |||||

Pb, % | ≤0.0015 | |||||

As, % | ≤0.0005 | |||||

Total Plate count, cfu/g | ≤1000 | |||||

E-coli, cfu/g | Negative | |||||

Yeast and mould, cfu/g | ≤100 | |||||

Remark: | we can produce according to your requirement. | |||||

8) Oil Drilling Grade CMC (Petroleum Drilling / Fracturing fluid Grade CMC)

Oil drilling fluid products: CMC-HV、CMC-LV、PAC-LV 、PAC-R、PAC-HV

Hosea Chem Sodium Carboxymethyl Cellulose be widely used in petroleum drilling field. Mainly as a viscosifier, rheology control agent and fluid loss agent used in drilling fluid,with strong ability of suspension,carrying drilling cutting effectively,protecting borehole wall,preventing loss of mud,protecting drill and thinning thickness of the mud cake;It is suitable for fresh water,sea water and saturated salt water mud with high yield rate,good alkali resistance and strong antibacterial properties. It has good thermal stability, and still can effectively reduce water loss at temperature above 150 ℃ . In the completion fluid,it mainly controls the viscosity of fluid、suspends the weight、carries the filler and prevent the fluid loss.

Specification n | Filtration loss | Thickening | Shale inhibition |

PAC-HV | ☆☆☆☆ | ☆☆☆☆ | ☆☆☆☆ |

PAC-LV | ☆☆☆☆ | ☆☆ | ☆☆☆ |

CMC-HV | ☆☆ | ☆ | ☆☆ |

CMC-LV | ☆☆ | ☆ | ☆ |

☆Degree

CMC-LVT Specification:

项目 Requirement | 标准 Standard |

Starch or starch derivatives presence | 无 no |

Solution properties | |

Viscometer dial reading at 600 r/min | ≤ 90 |

Suspension properties | |

Filtrate volume | ≤ 10mL |

CMC-HVT Specification:

Requirement | Standard |

Starch or starch derivatives presence | 无 no |

Solution properties | |

Viscometer dial reading at 600 r/min | |

In deionized water | ≥ 30 |

In 40g/L salt solution | ≥ 30 |

In saturated salt water | ≥ 30 |

Suspension properties | |

Filtrate volume | ≤ 10mL |

9) Paper Making Grade CMC

In paper-making industry, carboxymethylcellulose can be used in the pulping process. It can increase the residence rate and humidity. When it is used in the surface glueing or pigment excipient, it can increase the inner adhesive force, reduce the printing dust, and improve the printing quality; when it is used in the paper coating, it can contribute to the pigment’s distribution and liquidity, improve the paper’s fineness, smoothness, optical performance, and printing adaptability. Generally, the recommended dosage is 0.3-1.5%. Due to its firm-forming property and oil resistance, which is the property of water-soluble high polymer, CMC is a widely used additive with practical value in paper-making industry.

ZZH-8204 | ZZH-8205 | ZZH-8206 | ZZH-8207 | ZZH-8208 | |

Appearance | White to white cream powder | ||||

Viscosity 2% , 25℃, mPa.s | <20 | 20-50 | 50-150 | 300-800 | <20 |

Purity, % | ≥95 | ≥90 | ≥80 | ≥70 | ≥80 |

Degree ofSubstitution(D.S) | 0.70-0.95 | 0.70-0.90 | 0.60-0.80 | 0.60-0.80 | >1.0 |

pH (25℃, 1% solution) | 6.0-8.5 | ||||

Loss ondrying(H2O),% | ≤10.0 | ||||

Remark: | we can produce according to your requirement. | ||||

10) Textile Dyeing Grade CMC (Sodium Carboxymethyl Cellulose)

In textile industry, CMC can be used as the thickening agent of the slurry and printing and dyeing liquid, and it can make the textile printing firm and clean.

Filtration :The original paste contains no insoluble substances, filterability is very good. Stability:lt's quite stable when used in salt and weak acid medium,it can be used non-ionic and anionic additives together. Colour Yield:It can improve the color yield rate and increase the vividness mixed use with other printing paste. Compatibility:It can be used with sodium alginate,the efficiency of the dyeing can be greatly improved.

TG-3 | TG-4 | TG-5 | TG-6 | TG-7 | |

Appearance | White to white cream powder | ||||

Viscosity 1% , 25℃, mPa.s | 200-500 | 500-1000 | 1000-2000 | 2000-3000 | >3000 |

Purity, % | ≥98 | ||||

Degree ofSubstitution(D.S) | 1.1-1.2 | 0.80-0.90 | ≥1.0 | ≥1.0 | 1.0 |

pH (25℃, 1% solution) | 8.0-11.0 | 6.0-8.5 | |||

Loss ondrying(H2O),% | ≤10.0 | ||||

Remark: | we can produce according to your requirement. | ||||

11) Washing Powder Grade CMC

In Washing Powder Industry, CMC can be used as an anti-soil redeposition agent, which can prevent the dirt from the synthetic detergent from being deposited on the fabric again. Adding 0.5-2.0% in synthetic detergent can obtain satisfactory results.

LD-XYF-1 | LD-XYF-2 | LD-XYF-3 | LD-XD-1 | LD-XD-2 | |

Appearance | White to white cream powder | ||||

Viscosity 1% , 25℃, mPa.s | 5-40 | 5-40 | 5-40 | 100-500 | 500-800 |

Purity, % | ≥55 | ≥65 | ≥72 | ≥72 | ≥72 |

Degree ofSubstitution(D.S) | 0.5-0.7 | ≥0.8 | |||

pH (25℃, 1% solution) | 8.0-11.5 | 8.5-10.0 | |||

Loss ondrying(H2O),% | ≤10.0 | ||||

12) Welding Electrode Grade CMC

When used in welding electrode, CMC can improve its appearance, its quality, and its eccentricity. Also, CMC can reduce the welding electrode’s breakage rate. What’ more, CMC can increase the welding electrode’s viscosity and allow it to shape up easily, etc. Due to CMC’s good acid resistance and salt tolerance, the liquid with CMC will have high stability, which is appropriate for the alkaline battery and zinc-manganese battery.

13) Pharmaceutical Industry Grade Sodium Carboxymethyl cellulose

CMC used in oral medicine, can help the medicine be easily processed into some shape and it can help medicine be digested and absorpt, used in ointment as dispersant and humectant, and in some syrup, used as suspending agent emulsifier, stabilizer and so on.

14) Civil Engineering Industry CMC

CMC used in construction mud slurry, can reduce water loss, improve the water retention and increase the strength; adding CMC can also make the materials stable and exist longer period.

15)Industrial /Mosquito Coil Grade CMC

To make the ingredients evenly conglutinate, which in turn endows the mosquito-repellent incense with good formability, and allows it to have smooth surface.Improve the mosquito-repellent incense’s tenacity, and keep it from fracture and breakage. Allow the mosquito-repellent incense’s properties and pesticide effect distribute evenly.

4.Product Details of Sodium Carboxymethyl Cellulose

Appearance of Sodium Carboxymethyl Cellulose: White or slightly yellowish, free-flowing powder.

5.Product Qualification of Sodium Carboxymethyl Cellulose

With competitive prices, stable quality, and good service, Hosea Chem® Sodium Carboxymethyl Cellulose (CMC) are highly recognized and praised by our customers. Meantime, we provide technical support of each product and marketing competition survey to help customers further enlarge their business easily.

6.Deliver, Shipping And Serving of Sodium Carboxymethyl Cellulose

Packaging: 25kg/bag or according to client request

Delivery Detail: 2 weeks after confirm order.

Shipping: by sea.

Serving:

Ⅰ. over 10 years of export trading experience.

Ⅱ. 7x24 hours custome service, help you to solve your questions anytime you want.

Ⅲ. Arrange the orders and shipping with cus requests in time, According to the different countries export policy provide complete customs clearance documents.

Ⅳ. Provide a price trend, ensure the clients can know about marketing informations in time.

Ⅴ. Fast response, fast service .Emails will be replied in 12 hours. Ensure your questions will be answered in time.

7.FAQ

Q1.What's the payment terms?

T/T or L/C.

Q2.What's the shelf life for the cargos?

Our product's shelf life is 2 years, which is based on dry and ventilated storage.

Q3.What's the delivery time?

We usually deliver the cargos within 10~20 days after receiving customer's prepayment and original LC.

Q4.What documents can we supply?

Commercial Invoice, Packing List, Certificate of analysis, Certificate of Origin, Health Certificate issued by CIQ with embassy legalized, Bill of Loading etc.

The documents will be sent by Express within 24 hours against your full payment.