Tetrabromobisphenol A/TBBPA

Hosea Chem® has been supplying Tetrabromobisphenol A (Cas 79-94-7) with high quality and competitive price for many years, covering most of the European, American, etc. Send Inquiry

Product Description

Tetrabromobisphenol A/TBBPA

Chemical Name: Tetrabromobisphenol A;TBBPA;CAS 79-94-7

Cas No.: 79-94-7

EINECS No.: 201-236-9

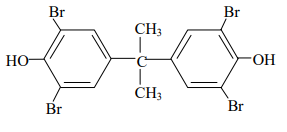

Chemical Formula: C15H12Br4O2

Molecular Weight: 543

Melting point≥: 182°C

Boiling point: -316°C

Density: 2.18g/cm3

Molecular Structure:

Description

It is a white powder. A monomer for flame-retardant epoxy, polyester and polycarboante resins. Tetrabromobisphenol A is a white crystalline with a moderately high molecular weight, low water solubility, and moderately high lipophilicity (as indicated by log Kow). Only about 4% of the particles are<15 μm in diameter, and thus, little (<4%) is expected to be respirable (<10 μm in diameter) and absorbed from the lung after inhalation exposure.

Tetrabromobisphenol A/TBBPA Standard

Appearance: White crystal

Content (%) ≥: 99.6

Bromine Content (%): 58.8

Specific Gravity: 2.18

Chroma (Acetone): 40.0

Chroma (Methanol): 15

Application

1. Used as a flame retardant additive to plastics (ABS, phenolic, unsaturated polyester resins, and epoxy resin circuit boards), paper, and textiles; Also used as a plasticizer and chemical intermediate.

2. Tetrabromobisphenol A is widely used as a reactive flame retardant to produce a bromine-containing epoxy resin and polycarbonate, and as intermediates for the synthesis of other complex flame retardant, also as an additive flame retardant for ABS, HIPS, unsaturated polyester rigid polyurethane foams, adhesives and coatings.

3. The main use of TBBPA is as a reactive flame retardant in epoxy resins for printed circuit boards in computers, telecommunications equipment, industrial controls and automotive electronics. Both hydroxyl groups on TBBPA can be reacted with epichlorohydrin under basic conditions to form the diglycidyl ether, which is widely used in epoxy resin formulations. TBBPA is also used in polycarbonate and ether polyester resins and is used as a chemical intermediate for the synthesis of tetra-bromobisphenol A allyl ether, -bis(2-hydroxyethyl ether), -carbonate oligomer, and -diglycidyl ether. TBBPA is also used as a flame retardant in plastics, paper, and textiles, and as a plasticizer in adhesives and coatings. Being covalently bound to the polymer limits exposure to unbound excess chemical used in the manufacturing process.

Storge & Handling

Store in tightly closed containers in a cool, well-ventilatedarea.

Packing

25KG/ BAG or can be customized as per customer requirement