Terephthalic Acid (TPA)

Hosea Chem® has been supplying Terephthalic Acid (TPA) (CAS 100-21-0) with high quality and competitive price for many years, covering most of the European, American, etc. Send Inquiry

Product Description

Terephthalic Acid (TPA)

Chemical Name:Terephthalic Acid;TPA;CAS 100-21-0

EINECS No.: 202-830-0

Chemical Formula: C8H6O4

Molecular Weight: 166.13

Melting point: >300 °C (lit.)

Boiling point: 214.32℃

Flash point: 260°C

Density (25 °C): 1.58 g/cm3

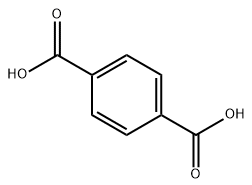

Molecular Structure:

Description

Terephthalic Acid, an organic compound resembling a white powdery substance, claims its prominence as the most abundant dicarboxylic acid. It possesses combustible properties, though with low toxicity, and remains solid at room temperature, defying the conventional melting point upon heating. Solubility reveals itself in alkaline solutions, exhibiting only slight solubility in hot ethanol. However, it remains insoluble in water, ether, glacial acetic acid, and chloroform.

Terephthalic Acid (TPA) Standard

Appearance: White Powder

Content %≥: 99.0

Density (25 °C):: 1.58 g/cm3

Vapor Pressure (20 °C): <0.01 mm Hg

Refractive index n20/D: 1.5100

Exposure Limit: ACGIH: TWA 10 mg/m3

Application

TPA finds its primary application in PETG production, which accounts for over 90% of global TPA usage. Additionally, TPA is utilized in manufacturing plasticizers, comprising two distinct categories. The first category encompasses dioctyl terephthalate (DOTP), a high-quality plasticizer obtained through the esterification reaction between TPA and industrial octyl alcohol (2-ethylhexyl alcohol). DOTP has a high flash point and specific resistivity, making it suitable for producing heat-resistant cable materials with stringent insulation requirements. The second category consists of polyester plasticizers derived from the esterification of TPA and polyols such as diethylene glycol, trimethylene glycol, glycerol, propylene glycol, and butanediol, among others. The molecular weight of these polyester plasticizers generally falls within the range of 1000-4000. Notably, the relative molecular weight of polyester as a plasticizer is much smaller than polyester used in chemical fiber and plastic packaging applications.

Storge & Handling

Providing a nurturing environment for TPA is essential. Optimal storage conditions involve a dry and well-ventilated area shielded from direct sunlight, moisture, and heat sources. Safeguarding the material from air and moisture exposure prevents degradation and ensures its enduring quality.

Packing

25KG/Bag