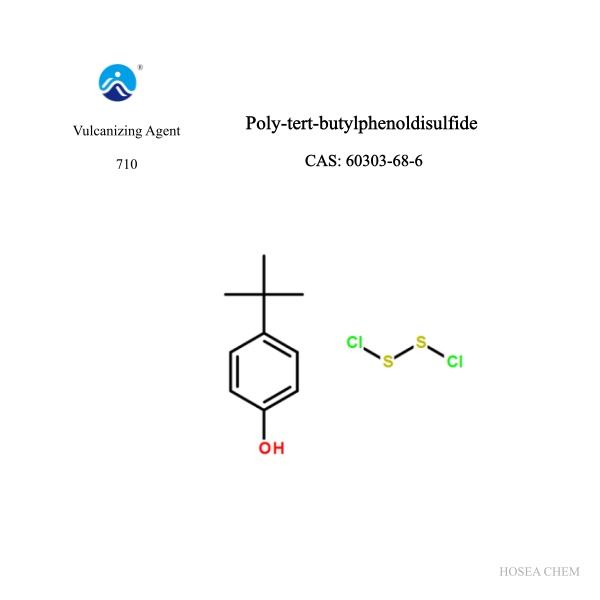

Poly-tert-butylphenoldisulfide

Hosea Chem® has been supplying Poly-tert-butylphenoldisulfide (CAS 60303-68-6) (Vulcanizing Agent VTB-710, Vultac 5) with high quality and competitive price for many years, covering most of the European, American, etc. Send Inquiry

Product Description

Hexamethylenediamine Carbamate

Specification of Product

Product Name : Hexamethylenediamine Carbamate; 4-tert-butylphenol;chlorosulfanyl thiohypochlorite

Grade: Ⅰ Grade

Molecular Formula: C10H14Cl2OS2

Cas No.: 60303-68-6

Poly-tert-butylphenoldisulfide Quality Standard

Appearance: Brown resin-like

Softening point temperature,℃: 75-95

Sulfur content, %: 25-28

Packaging, transportation, and storage

Package:25kg/Kg.

Avoid shine, rain, and high temperatures in transportation.

Store the products in cool, shady, and ventilated conditions, keep far away from antioxidants.

Poly-tert-butylphenoldisulfide Applications

Poly-tert-butylphenoldisulfide (Vulcanizing agent DH710), chemically known as alkylphenol disulfide, is marketed as VTB-710 or V5 (Vultac 5).

Poly-tert-butylphenoldisulfide (Vulcanizing agent DH710) appears as a brown, resinous powder or solid with a total sulfur content of approximately 28%. The higher the sulfur content, the higher the softening point and density of the resin. Generally, the relative density of the resin is 1.1-1.4, and the softening point is 75-95°C.

Poly-tert-butylphenoldisulfide (Vulcanizing agent DH710) exhibits exceptional performance as a vulcanizing agent for diene rubbers, particularly chlorobutyl rubber. Containing 28% combined sulfur, it completely replaces sulfur, ferrocene (DTDM), and N,N'-caprolactam disulfide (DTDC) in semi-active and active vulcanization formulations.

When heated, this product releases active sulfur, producing a vulcanization without causing the vulcanized rubber to experience surface elongation caused by the migration of internal additives as tensile stress. Products vulcanized with this vulcanizing agent exhibit excellent heat resistance and resistance to high temperatures and oxidative aging. During the vulcanization process, no carcinogenic nitrosamines are formed.

Poly-tert-butylphenoldisulfide (Vulcanizing agent DH710) is a vulcanizing agent specifically designed for all-steel and semi-steel radial tires. It enhances the activity of chlorobutyl rubber, allowing for simultaneous vulcanization, improving vulcanization efficiency, and reducing product defect rates. Additionally, it can act as a tackifier for styrene-butadiene rubber/acrylonitrile-butadiene rubber, enhancing the handling properties of styrene-butadiene rubber/acrylonitrile-butadiene rubber and improving the processing properties of blended rubbers.

Poly-tert-butylphenoldisulfide (Vulcanizing agent DH710) is primarily used in tire innerliner rubber, tires (especially white tire sidewalls), tire surface rubber, rubber ribs, and breaker rubber. It is also used in conveyor belts, high-pressure rubber hoses, high-speed rubber rollers, and gaskets.