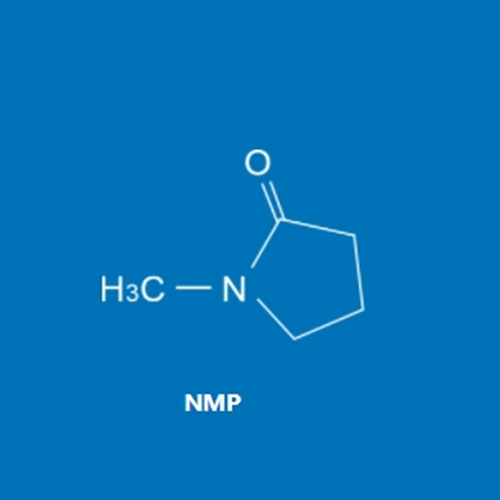

N-Methyl Pyrrolidone

HOSEA CHEM®N-Methyl-2-Pyrrolidone (NMP,Cas 872-50-4) is a nitrogen heterocyclic compound with a series of excellent physical and chemical properties. It is non-toxic, has high boiling point, strong polarity, low viscosity, low corrosiveness, high solubili Send Inquiry

Product Description

Product Information

Chemical Name: N-Methyl-2-Pyrrolidone

Appearance: Colorless transparent liquid

CAS No.: 872-50-4

Formula: C5H9NO

Refractive Index nD20: 1.468-1.471

MolecularWeight: 99.10

Synonyms: 1-methyl-2-pyrrolidinone; NMP; M-pyrol; Methylpyrrolidone; 1-Methyl-5-Pyrrolidinone; N-Methylpyrrolidone; N-Methyl-2-Pyrrolidone;

Chemical Structure:

Description

N-Methyl-2-pyrrolidone is a high boiling, polar aprotic, low viscosity, colorless to slightly yellow liquid, with a faint amine odor. NMP is miscible with water and conventional organic solvents like ethyl acetate, chloroform, benzene and lower alcohols or ketones. It is the cyclization product of 4-Methyl-Aminobutyric acid.

Specification

Item Reagent grade Electronic grade Industrial grade

Assay, %min. 99.9 99.9 99.5

Color, Hazan max. 15 20 25

Density, g/ml 1.032-1.035 1.032-1.035 1.032-1.035

Water, % max. 0.01 0.02

* Please refer to Certificate of Analysis for detailed specification

Physical Properties

AutoignitionTemperature 245°C

BoilingPoint 204°C

Density@25°C 1.03g/cm3

Dielectric Constant 10 kHz@25°C 32.2

Dipole moment@20°C 12.26 D(debye)

FlashPoint ClosedCup 91°C

FreezingPoint -24.2°C

HeatofCombustion 3023kJ/mol

Heat of Vaporization @20°C 54.5kJ/mol

pH 100 g/l@20°C 7.5-10

RefractiveIndex 1.4700

Specificheat @ 20°C 0.175kJ/mol.K

Surface Tension@25°C 41mN/m

VaporDensity (air= 1) 3.42

Vapor Pressure@20°C 0.324hPa

Viscosity @25°C 1.661mPa·s

Watersolubility Miscible

Applications

N-Methylpyrrolidone (NMP) is the lactam of 4-methylaminobutyric acid and a very weak base. NMP is a chemically stable and powerful polar solvent. These characteristics are highly useful in a variety of chemical reactions where an inert medium is of concern. Despite the stability of NMP, it can also play an active role in certain reactions: hydrolysis, oxidation, condensation, conversion with chlorinating agents, polymerization and o-alkylation, and related reactions.

Recovery of Pure Hydrocarbons in Petrochemical Processing

A well-established application for NMP is the large-scale recovery of hydrocarbons by extractive distillation. This technique utilizes the high solubility of hydrocarbons in NMP and the fact that differences in volatility are sometimes considerably increased in the presence of NMP. Compared to other commercial solvents and extraction media, NMP offers the following advantages: no azeotropes are formed with hydrocarbons; NMP is very resistant to heat and chemicals; and NMP has a favorable toxicological and environmental profile.

Desulfurization of Gases

High concentrations of acidic compounds are often present in natural or synthesis gases. Examples are hydrogen sulfide, carbon oxysulfide, carbon dioxide and organic sulfur compounds. Rather than applying a chemical process, they are removed by physical scrubbing in several stages with a mixture of NMP, alcohol and water.

Plastics

NMP is a widely used industrial solvent for natural and synthesis plastics, waxes, resins and various types of paints. It dissolves polymers, such as cellulose derivatives, polyamides, polyimides, polyesters, polystyrene, polyacrylonitrile, polyvinyl chloride, polyvinyl pyrrolidone, polyvinyl acetate, polyurethanes, polycarbonates, polyethersulfones, polysulfones, polyethers and many copolymers

Surface Coatings

NMP is a non-corrosive high boiler with excellent solvent power and chemical resistance. Thus, NMP improves the properties of many surface coating systems. In particular, these effects are favorable for baked coatings that are cured at relatively high temperatures. NMP allows the production of highly filled paints and finishes. Since it improves the rheological properties, paints with superior flow-out and covering power are obtained. Hence, the coatings are more homogeneous, non-porous and non-cratering, and they display greater resistance to chemicals and higher mechanical strength

Paint Stripping and Cleaning

Due to its high solvating power for plastics, resins, oil and grease, NMP has been successfully employed as an ingredient in paint removers, cleaners and degreasers. NMP can be used alone or in blends for removal of oil, carbon deposits and other tarry polymeric residues from metal chambers, pistons and cylinders, as well as for wet cleaning of combustion engines.

Plant Protection / Agrochemicals

NMP can be used as a solvent or co-solvent for the formulation of insecticides, fungicides, herbicides, seed treatment products and bioregulators where highly polar compounds are required. NMP is given preference over other highly polar solvents because it is exempt from the requirement of a tolerance when used as a solvent or co-solvent in pesticide formulations applied to growing crops, and it possesses a favorable toxicological and environmental profile.

Electronics

The production of integrated circuits (ICs) calls for products of very high purity. The Electronic Grade NMP exceeds in all points the standard established by SEMI (Semiconductor Equipment and Materials Institute). This makes NMP a desired solvent for the electronic industry and producers of printed circuit boards. Blends of NMP with common solvents are utilized for the cleaning and degreasing of single-crystal silicon wafers for ICs.

Packaging

Iron drum: (net weight 200kg),80 drums(16,000kg)/20"FCL

Paint iron drum: (net weight 200kg), 80 drums (16,000kg)/20"FCL

HDPE drum: (net weight 200kg), 80 drums (16,000kg)/20"FCL

IBC drum: (net weight 1000kg), 20 drums (20,000kg)/20"FCL

ISO TANK: (net weight 20MT), 20,000kg / 20"FCL

Safety

Care should be used when handling NMP. Skin contact should be avoided.

Contact can result in irritation; prolonged contact can result in redness and dermatitis. Butyl rubber or FEP Teflon gloves are recommended when handling NMP. A good skin cream should be used after washing the affected area. As with all solvents, the workplace should be well ventilated and safety goggles must be worn.

Always refer to the Material Safety Data Sheet (MSDS)

Storage & Handling

Stored in cool and airy place; away from fire and heat; handle with care; no breakage, avoid leakage

It is valid for 3 years under proper condition.