Product Description

Ethyl Cellulose provides excellent functionality in many industrial applications. It offers an attractive range of physical properties and can be blended with other materials to achieve intermediate characteristics.

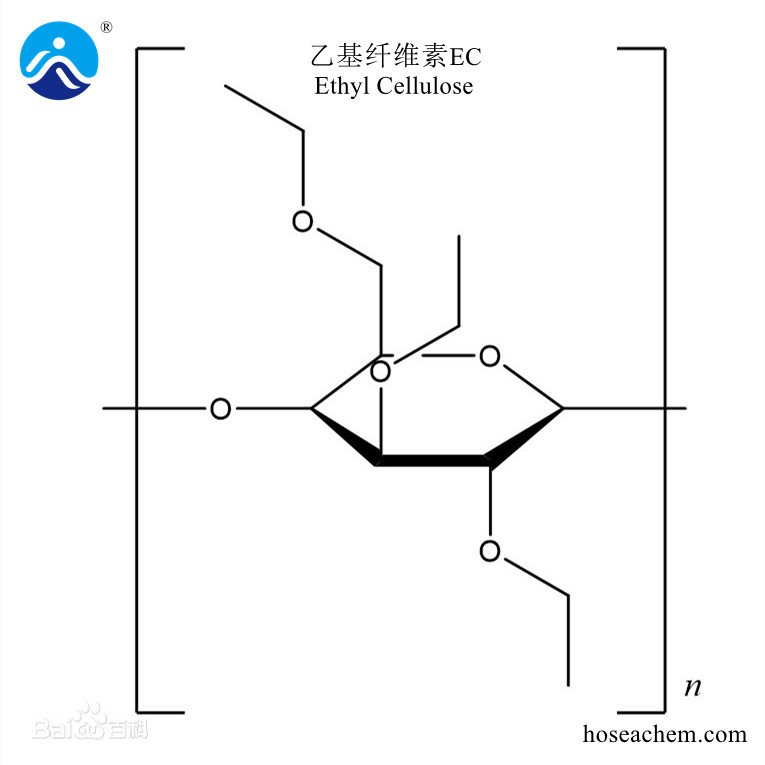

Brief introduction

Ethyl Cellulose is widely used in a variety of paints, surface coatings such as metal, paper products, paints, rubber coating, hot melt coating and integrated circuit; for the ink, such as magnetic ink, gravure and flexographic printing inks; for cold material ; for the specialty plastics and special deposits, such as rocket propellant coated with; for insulation and cable coatings; for suspension polymerization of polymer dispersant; for carbide and ceramic adhesives; for the textile industry for printing paste and so on.

Technical specification

Item | K grade | N grade |

Ethoxy (WT%) | 45.5-46.8 | 47.5-49.5 |

Viscosity (mPa.s) (5% solu., 20℃) | 4, 5, 7, 10, 20, 50, 70, 100, 150, 200, 300 | |

Loss on drying (%) | ≤3.0 | |

Residue on ignition (%) | ≤0.4 | |

Organic solvent method of solubility and dissolution

EC can be dissolved in various organic solvents, such as ethanol, isopropyl alcohol, other alcohols, ketones, aromatic and so on. Common solvent (volume ratio):

a. Toluene:Ethanol = 4:1

b. Ethanol

c. Acetone:Isopropanol = 65:35

d. Toluene:Isopropanol = 4:1

e. Methyl Acetate:Methanol = 85:15

Alcohols and aromatics in the viscosity of the mixture, going down with alcohol content higher, when alcohol accounts for 30-35%, the lowest viscosity of the composition. Dissolution method: the EC under the stirring slowly add the container filled with a solvent until complete wetting dissolved.

Applications

Specification | Applications |

EC N-150, EC N-200 | Conductive pastes |

EC N-50, EC N-100 | Hot melts |

EC N-7, EC N-10 | Paper coatings |

EC N-7, EC N-10, EC N-20 | Printing inks |

EC N-200 | Adhesives |

EC N-50 | Fluorescent lighting |