Decabromodiphenyl Ethane Masterbatch

Hosea Chem® has been supplying Decabromodiphenyl Ethane Masterbatch (Cas 84852-53-9) with high quality and competitive price for many years, covering most of the European, American, etc. Send Inquiry

Product Description

Decabromodiphenyl Ethane Masterbatch/DBDPE Masterbatch

Chemical Name: Decabromodiphenyl Ethane Masterbatch; DBDPE Masterbatch; CAS 84852-53-9

Cas No.: 84852-53-9

EINECS No.: 284-366-9

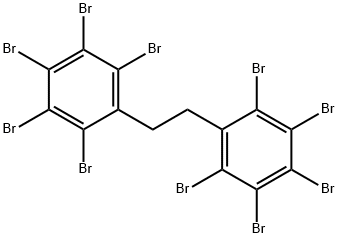

Chemical Formula: C14H4Br10

Molecular Weight: 971.22

Melting point≥: 340°C

Boiling point: 676.2°C

Density: 3.25 g/cm3

Molecular Structure:

Description

DBDPE masterbatch is made of DBDPE powder, nucleating agent, dispersing agent etc. Granulation is extruded by the twin-screw after efficient mix. This masterbatch as a flame retardant is not only mainly used in the engineering plastics such as electronic industries, electrical appliances, lamps and lanterns etc., but also wildly used in wire, cable, pipe and sheet. The usage method and adding amount is equal to powder. Carrier can be adjusted according to customer’s demand.

Decabromodiphenyl Ethane Masterbatch Standard

Br-120 Br-140

Appearance: White granules White granules

Content (%) ≥: 90 88

Whiteness (%) ≥: 89 89

Water (%) ≤: 0.05 0.05

Density g/cm3 : 2.5 2.5

Carrier: Modified POE EVA

Application: PA/PP/PBT/PE/PC EVA/PE/ABS/HIPS

Application

Decabromodiphenyl Ethane Masterbatch (DBDPE Masterbatch) is a new high efficiency, environment fridendly flame retardent developed by our company and Beijing Institute of Technology. The product has properties of high bromine content, excellent thermal stability, low toxicity and UV-resistance. Decabromodiphenyl Ethane (DBDPE) is used in high-impact polystyrene, engineering plastics,wires and cables, insulator, elastomer and thermoset plastics etc.

Storge & Handling

Keep away from heat, sparks, and flame. Keep away from sources of ignition. Store in a tightly closed container. Store in a cool, dry, well-ventilated area away from incompatible substances.

Packing

25KG/BAG; 1000KG/BAG; 25KG/DRUM.