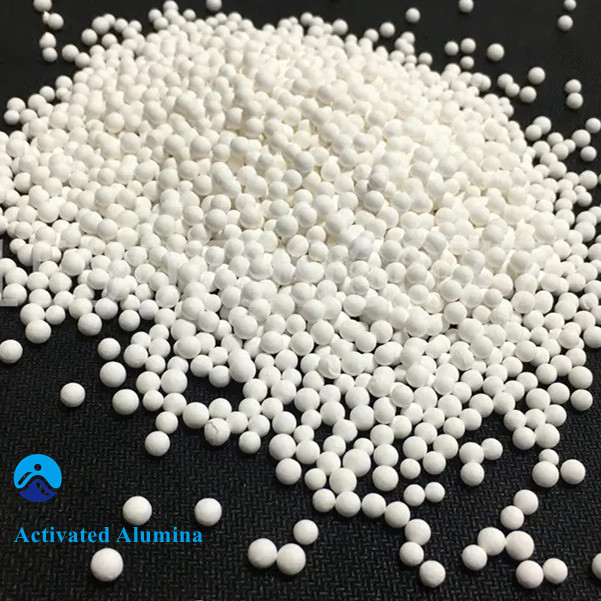

Activated Alumina

Hosea Chem® has been supplying Activated Alumina with high quality and competitive price for many years, covering most of the European, American, etc. Send Inquiry

Product Description

Activated Alumina

Description

Activated Alumina, also known as activated bauxite. Alumina used in catalysts is usually called "Activated Alumina". It is a porous, highly dispersed solid material with a large surface area. Its microporous surface has the characteristics required for catalysis, such as adsorption performance, surface activity, excellent thermal stability, etc., so it is widely used as a catalyst and catalyst carrier for chemical reactions. Spherical activated alumina pressure oil adsorbent is a white spherical porous particle. The activated alumina has a uniform particle size, a smooth surface, high mechanical strength, strong hygroscopicity, and does not swell or crack after absorbing water. It remains in its original state. It is non-toxic, odorless, and insoluble in water and ethanol. Activated alumina is an efficient desiccant for deep drying of trace water, suitable for heatless regeneration devices.

Activated Alumina is generally produced by heating and dehydrating aluminum hydroxide. Aluminum hydroxide is also called hydrated aluminum oxide, and its chemical composition is Al2O3·nH2O. It can be divided into trihydrate aluminum oxide and monohydrate aluminum oxide according to the number of crystal water contained. After heating and dehydrating aluminum hydroxide, γ-Al2O3 can be obtained, which is commonly referred to as activated alumina.

Application

Activated Alumina for TBC removal in production of polyethylene and polymer.

Activated Alumina for ordinary gas and fluid dehydration.

Activated Alumina for arsenic and fluoride removal in water treatment.

Activated Alumina for absorption in producing hydrogen peroxide (H2O2).

Activated Alumina for catalyst carrier.

Activated Alumina for dehydrating and drying in air separation.

Factors affecting Activated Alumina

(1) Particle size: The smaller the particle size, the higher the adsorption capacity, but the smaller the particle size, the lower the particle strength, which affects its service life.

(2) Raw water pH: When the pH value is greater than 5, the lower the pH value, the higher the adsorption capacity of activated alumina.

(3) Raw water initial fluoride concentration: The higher the initial fluoride concentration, the greater the adsorption capacity.

(4) Raw water alkalinity: The higher the bicarbonate concentration in the raw water, the lower the adsorption capacity.

(5) Chloride ions and sulfate ions.

(6) Influence of arsenic: Activated alumina has an adsorption effect on arsenic in water. The accumulation of arsenic on activated alumina causes a decrease in the adsorption capacity of fluoride ions and makes it more difficult to elute arsenic ions during regeneration.

Storge & Handling

Keep container tightly closed.

Store in a cool, dark and well-ventilated place.

Packing

25kg Double layer woven bag.