A method for rapidly dissolving sodium carboxymethyl cellulose in battery slurry

2021-12-06A method for rapidly dissolving sodium carboxymethyl cellulose in battery slurry, including the following steps:

A. Mix sodium carboxymethyl cellulose and N-methylpyrrolidone at a mass ratio of 1:2 to 4 and stir thoroughly to obtain a mixed sodium carboxymethyl cellulose solution;

B. Add a certain amount of deionized water into the mixing barrel of the mixer, and then slowly pour it into step A while stirring the deionized water, Prepared sodium carboxymethyl cellulose solution;

C. Stir for 5 ~ 10min under the condition of vacuum 20~40Hz;

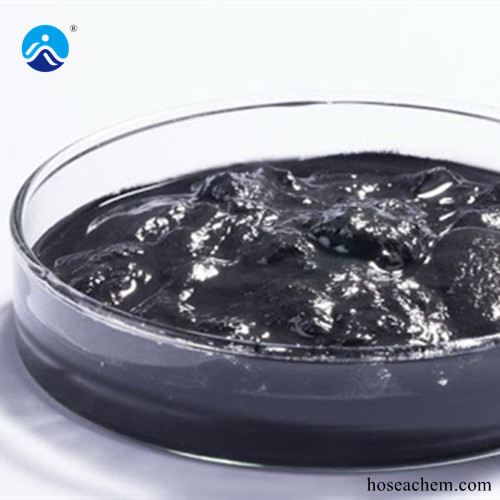

D. Clean up the gelatinous sodium carboxymethyl cellulose adhering to the stirring paddle and the wall of the barrel, and then stir for 30 min to 60 min under the condition of a vacuum of 20 to 40 Hz to obtain a fully dissolved sodium carboxymethyl cellulose glue solution .

In order to further illustrate the above steps, the following examples are listed first:

(1) Weigh 50g of sodium carboxymethylcellulose and 100g of N-methylpyrrolidone, mix and stir thoroughly to obtain a mixed sodium carboxymethylcellulose solution;

(2) Inject 3.283kg of deionized water into the mixing tank to prepare 1.5% sodium carboxymethyl cellulose glue;

(3) Rotate the stirring paddle while stirring the deionized water and slowly pour the sodium carboxymethyl cellulose solution prepared in (1), use a silica gel plate to clean the wet sodium carboxymethyl cellulose attached to the inner wall of the container and add it to the mixing tank Inside ;

(4) After adding the sodium carboxymethyl cellulose solution, stir for 5 min under vacuum 30 Hz;

(5) Use a silica gel plate to clean the gelatinous sodium carboxymethyl cellulose adhering to the stirring paddle and the barrel wall;

(6) Stir for 50min under the condition of vacuum 30Hz;

(7) Use strong light to observe the uniform light transmission of the glue, and the viscosity of the test glue is 2230mpa.s;

(9) After stirring, the glue liquid is kept in vacuum for use.