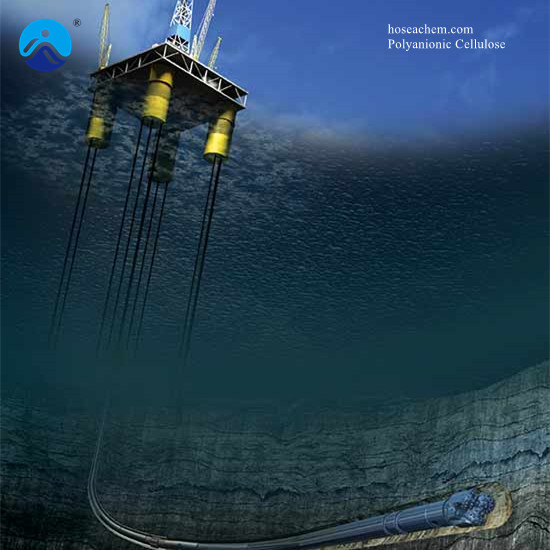

Deep well temperature resistant drilling fluid

2022-01-18Scope of application:

It is used for operation in the lower deep well section and high temperature well section (> 150).

Basic formula (kg/m3):

Pre-hydrated soil 10~20

Caustic soda 3~5

Soda Ash 1~2

Polyanionic Cellulose PAC-LV 4~8

SPNH 10~20

SMP 10~20

PF-THIN 3~5

PF-TEX 5~10

Common performance:

FV: 45 ~ 65 s

MW: 1.20~1.80 g/cm3

YP: 10~20 lb/100ft2

Gel: 5~10/8~20

pH: 9~10

FL: ≤4ml

HTHP FL: < 15ml

MBT: < 45g/l

Maintenance processing:

a. Use caustic soda and soda ash to control the pH, Ca2+, Mg2+ concentration of the system;

b. The content of soil in the control system is at a low level, and pre-hydrated soil is added to control the filtration loss and improve the quality of the mud cake. Before adding, the rubber must be treated with a diluent such as PF-THIN;

c. Use polymer deflocculants such as PF-THIN or lignosulfonate (FCLS), sulfonated lignite (SMC), sulfonated tannin (SMT), etc. to control the sticking of mud; the high soil content of the system causes When the viscosity is too high, the method of diluting with dilute glue should be used first.

d. PF-JLX and PF-WLD can also be used in this system to improve the inhibition of the system, and the amount of PF-JLX must be more than 3%;

e. Adding PF-TEX to enhance the anti-slump ability of the system; SMP and SPNH are used to control the HTHP fluid loss.